|

WORKIN' AND UNBODGIN'

Grand Funk's 'tron, now owned by Stewart Myers, is in for

repair

<-- Stewart's machines in various states of repair

(as of this MONEYPIT most of the work was done, and Jerry was waiting for warmer

weather so the refinishing work could begin)

<-- Stewart's machines in various states of repair

(as of this MONEYPIT most of the work was done, and Jerry was waiting for warmer

weather so the refinishing work could begin)

See the unveiling of Stewart's machines in the

next MONEYPIT adventure!

SOME MACHINES ARE UNSOUNDLY BODGED!

Unlike two of the four M400s in Jerry's repair depot these days, Lee's #541

was never bodged by Sound Sales. As a review, here's what a Sound Sales

bodge is:

| Take a working M400 and wreck it. |

Whew--one of the lucky ones that escaped Sound Sales!

And how they did it:

| Move brackets from the tape take-up box from the bottom of the box to the

top. This weakened the M400's internal frame and often resulted in tapes

that were too high or too low when running over the tape heads and capstan and

entering the take-up box.

<-- Click for a bigger image. Note the results of

the weakened frame over time when you add the weight of the flywheel

and the motor belt tension. Eventually the machine becomes harder to

adjust.

<-- Click for a bigger image. Note the results of

the weakened frame over time when you add the weight of the flywheel

and the motor belt tension. Eventually the machine becomes harder to

adjust.

<-- Lack

of support under the take-up box--the whole assembly now sways <-- Lack

of support under the take-up box--the whole assembly now sways

<-- The

bracket is an OK idea to replace the wood wedges there originally, but

it's around the wrong way (the front-back slots should be on the box, the

up-down on the frame) and there's no corresponding support on the frame

sideboards under the take-up box, leading to the swaying and bending of the

frame <-- The

bracket is an OK idea to replace the wood wedges there originally, but

it's around the wrong way (the front-back slots should be on the box, the

up-down on the frame) and there's no corresponding support on the frame

sideboards under the take-up box, leading to the swaying and bending of the

frame |

| Improve the sound on each tape head. This was done by

bending/warping the pressure pad arms when all that was needed was an

adjustment using the slotted screw that holds each pad arm in place. |

| Squash two pinch rollers between the keyboard and the headblock for

improved stability during travel. Not really needed. Made track

selection harder. |

| Remove the stabilizing blocks on the side of the case near the motor.

Maybe they figured their other "improvements" meant that motor support was no

longer necessary? |

| Put a big sticker on the power supply proving the fine work that was done.

(Does nothing but lower the value of the machine.) |

| Charge the customer several hundred dollars. And for that privilege

the customer receives his machine back in worse shape than before. (This

was the fate of Larry Fast's M400---a machine he never used again, thus

changing music history.) |

|

BODGED AND

BURIED |

|

One way to tell a bodged machine or at least a machine that's got some

issues is to look at the depth of the pad arm and pinch roller adjustment

screws. Notice on this one the screws closer to the flywheel are down

more, some buried in the wood. This would be a symptom of the frame

starting to sag. (Now why is there "805" on that keyboard? I have

no idea! #805 is scratching his head, too...he has the original #805

keyboard!) |

The one thing Sound Sales did right:

| Replace the CMC-10 motor controller with an SMS-3. But because other

things were messed with, the improvement wasn't obvious.

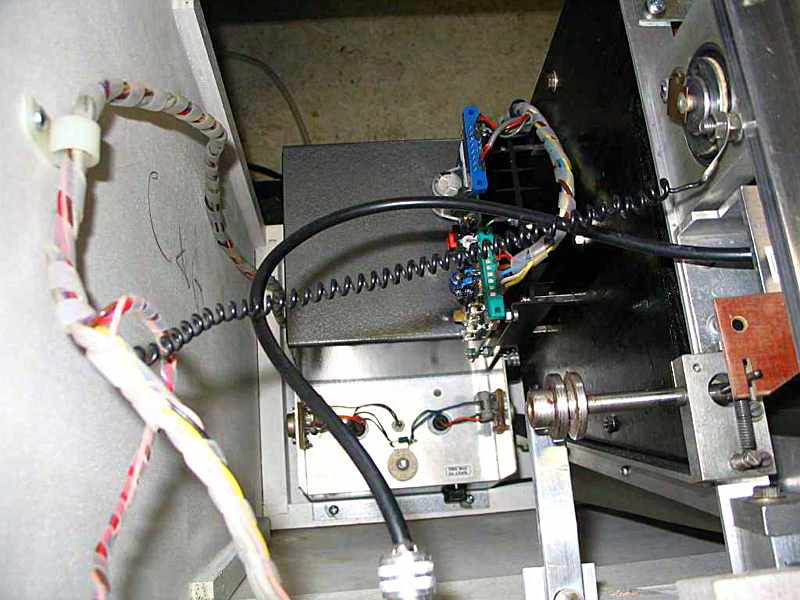

<-- SMS-3

<-- SMS-3 |

SOME MACHINES JUST NEED A LITTLE TLC

Lee's machine? Fairly straightforward, no bodging. It just needed

a tune-up to get it playing right.

Disassembly of #541

<-- Initial inspection/cleanup of the electronics.

Yep, the CMC-10 has to go!

<-- Initial inspection/cleanup of the electronics.

Yep, the CMC-10 has to go!

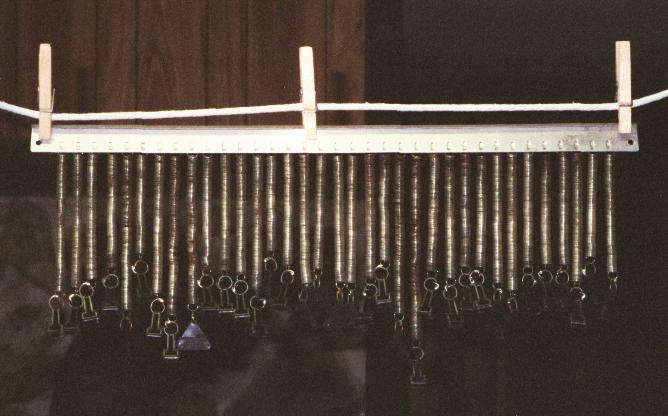

Tidying up the keyboard:

Hanging out your Mellotron laundry?

Those are the springs from Lee's tape frame after being cleaned

up...drying on a clothesline. Go light on the starch, Jerry!

Actually this is a cunning plan to locate the stretched and

knackered springs. What the heck, let gravity do the work!

| And what's a new tape frame without a new set of tapes? As you can

hear from "Leaving for the Black Sand",

Lee opted for:

- Ian McD Flute

- String Section

- Combined Choir

|

|

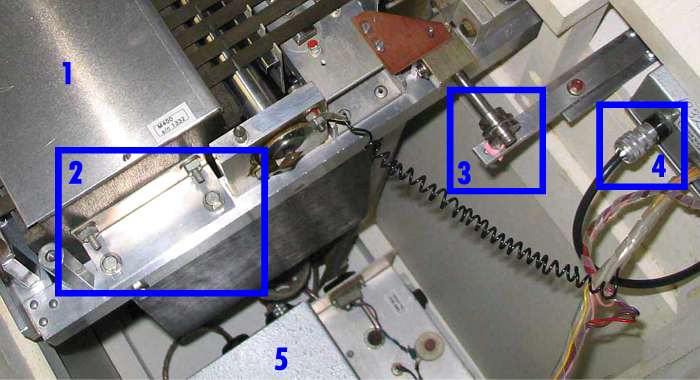

Now with the SMS-2 in-hand, it was time to modify the power

pack, swap in the new pitch control, fire up the motor, and look for 22 volts:

OK, 22.03 volts. I guess that's OK. :-)

|

Typical Korb Mods

These are typical JK mods to

Mellotrons that go through his shop. |

|

-

Take-up box cover. Jerry

fabricated these; they are available from him if you need one.

-

Orient the take-up box brackets

correctly (and make sure there is a set of brackets on the bottom of the

take-up box!); optionally replace the original wedges at the top with a

bracket if desired. Brackets have been fabricated and are available.

-

This is a new one. Several people

have complained about noise when changing the track selector or a rustling

noise or hiss on one track but not others. In consultation with John

Bradley of Streetly, a modification has been developed:

A small insulating piece of plastic isolates the bolt holding the pin of

the track selector. Note that there is a sleeve in the bolt hole as

well to keep the pin isolated from the track selector arm. The idea

is to electrically isolate the track selector pin from the arm.

-

Avoidance of "Screeching Cable Rot".

By now your M400's audio wiring is dust. When it fails, you will

hear a screech in your headphones, and you may magnetize your heads.

The audio cable between the headblock and preamp is replaced.

Optionally, the cable from the power pack to the volume jack and output

jack can be replaced as well (and probably should be by now).

-

The power supply is fixed up

cosmetically but more importantly the mains is rewired to avoid a

potential fire/shock hazard.

|

With the work done, this guy is about ready to be unveiled!

But first there's something you really need to know about your M400.

Yes--and this is unfortunately quite true--your little white beastie with black

feets is a fire hazard.-->

|