|

| |

Minimoog #6128

What's a Minimoog? Technically it's a 3 oscillator monophonic

synthesizer. Sonically it kicks some serious butt.

Lulu peers over the Minimoog

Around 1970 Bob Moog borrowed many components and ideas from his large modular

synthesizers and simplified them. What you have is a small Moog modular synth

without patch cables. All the routing is defined for you, and all you have

to do is twiddle knobs or flip some switches. Modulation (affecting one

signal with another) is limited, there's no oscillator sync, and the unit

doesn't even do well with external voltages coming in (due to keyboard voltage

sag, which is fixable from what I understand). But it sounds GREAT, and

it's a joy to "program" (OK, twiddle).

And you want to "save" those neat sounds you just twiddled in? The

Minimoog has unlimited memory capacity because it uses one of the oldest and

most reliable storage mechanisms ever devised: the pencil. :-)

The Minimoog's simplicity may lead you to think that this synth is limited, but you'd be

wrong. Yes, it has a particular overall sound, but within that range you

can create all kinds of wonderful noises, from thunderous crashes to screaming

lead lines to bizarre blips and bleeps.

Repairs

In August 2002 ol' #6128 decided to have some problems of its own---beyond

the squirrely keyboard it's always had. Fortunately the schematics are

freely available. You can get some from

Synthfool, and there are others tucked around the 'net (best search engine

is Google---through it I even found a

potential source for the TelLabs Q81 temperature compensating (tempco) resistor).

Anyway, here are the problems that Minimoog #6128 decided to start having and

what I did (or am trying to do) about them.

| Problem: OSC 1 way too high in pitch, was intermittent then

almost completely failed, went back to intermittent after all the work below.

When it is misbehaving, pin 5 on IC2 (SG3821N) churns out an unstable waveform

several times too high in frequency, along with a voltage that is too high.

You need to turn the range to 32' or lower to hear anything other than white

noise and the filter opening/closing. Quickly short/release pins 5 &

6 on IC2, and OSC 1 may work for a little while, although you'll hear an

unstable pitch every now and then. Eventually it goes back to being

wonky.

Fix: The problem seems to

have gone away on its own right now, but only after replacing several

components on the oscillator board (details below)--not including the big

polystyrene capacitor for OSC 1. So let's keep the fingers crossed, eh?

Attempted:

- Examine voltages and ohms. OSC 1 and OSC 2 are fairly close, being off

by fractions of a volt here and there. I can find no shorted resistors,

transistors, or caps.

- Examined the waveforms coming off IC2:

Pin 5 is crappy, its equivalent in OSC 2 Pin 8 is snazzy. The voltage at

Pin 5 is different when OSC 1 is working vs. when it is not by about 3

volts.

- Swap the 2 SG3821N ICs

- Replaced IC3 (741 op-amp) and put into an IC socket

- Replaced capacitor C2. OSC 1 worked GREAT for about 5 seconds after

initial power up, then went crappy again.

- Replaced capacitor on top of R78 (duh...I think it's just an RF

filter...amateur screw up!)

- Replaced the Molex sockets under IC2 with an IC socket (the Molex socket's

pins are not insulated and can short together)

- Replaced the SG3821N (IC2) with a CA3046 from Mouser (an LM3046 clone, a

stable replacement for the SG3821N IC)

- Replaced IC1 (741 op-amp) and put into an IC socket

- Replaced R19 (1K resistor in the tempco circuit)

- Replaced the TelLabs tempco resistor with a regular 1K resistor temporarily,

didn't help, so I put it back in

After that, other possibilities:

- Replace the Mallory SXM110 .01uF 2.5% 160V polystyrene cap (C1), not easy to

find. The closest I've found is an axial polystyrene cap at 50V, 5%,

which should work. I also ordered some 100V 1% capacitors that are not

polystyrene but are another plastic.

- Replace tempco resistor, not easy to find

And when all else fails:

- Bring it somewhere...:-)

|

| Problem: OSC 1 square wave gone.

Fix: Q11 (2N4058 transistor) shorted, easy to find with an ohm meter.

I replaced it, and the square waves are back. The square waves sound

a bit more brash than OSC 2 or OSC 3 now, so this may have changed the sound

of the machine. Or that may all be in my mind. |

| Problem (7-Nov-2004): OSC 2 dead. Was fine, all of a

sudden went belly up.

Fix: IC5 (a 741 op-amp) had low

voltage on pin 3. The op-amps for the other two oscillators had higher

voltage. I replaced the op-amp, and OSC 2 came right back. |

I've been attempting to bring the keyboard back to good playing condition.

The Pratt & Read keyboards aren't the best things, and this one is feeling its

oats.

| Problem: "Squirrely" notes--notes that won't hold a tone

constant and chirp like a warbler. I chased this into the keyboard, and

it's mostly on the notes next to the "bridges" that hold the buss bars in

place. It's the spring contact with the CV buss bar (the buss bar over

the resistors)---it does make contact, but the buss bar seems to bend "just

enough" to cause trouble.

Fix: Turning the buss bars took care of this. Not just the CV

buss bar, but the others as well. Eventually I hit upon a combination

that worked just fine. Sure, some of the notes are at tiny bit off---a

slight rise in pitch at release, for example. But no more squirrels!

Attempted:

- Cleaning the buss bars and springs. This generally works for exactly

one keypress.

- Turning the buss bar a little. This made a difference, but it's not

100%. I'm going to try messing about with this some more.

After that, more possibilities:

- Maybe the key stops (where the bushings are) are too high and can be bent

down a millimeter or two. Nawww, couldn't be that easy...

- I may try to fashion my own "bridge" to hold the

buss bar more firmly in place. Yes, OK, a hack.

- Perhaps the existing bridges moved around a bit. Unfortunately

loosening and moving them a smidge requires major surgery (removal of the buss

bar PCB).

And when all else fails:

- That's what the Kenton is for. :-) (Although the keyboard is

pretty nice after the bushings were replaced.) |

| Problem: The Mini's Pratt & Read keyboard (sometimes seen as

Pratt-Reed keyboard) has one key too high in the front, various key clicks,

and sloppy

action.

Fix: Replace the Pratt & Read bushings. These are little

rubber stoppers under the fronts of the keys, and they deteriorate as the synths age. Eventually you'll have uneven keys, your keys will click,

and the action will be uneven.

I have so far found two solutions to this, one from

Virtual

Music in Vienna and one from

Archive Sound. I purchased the Pratt & Read bushings from Rich at

Archive Sound, and I have

installed them. Here's how it went.

|

Archive Sound Pratt & Read Replacement Bushings

The promise of new life in the old Pratt & Read

I purchased brand new keyboard bushings from

Archive Sound. These

replace the old rubber bushings underneath the fronts of the keys.

These bushings cushion the key press and key release, and the Archive

Sound web page promises a completely different feeling keyboard.

So...Do they deliver?

You get a series of these bushings in your package, in my case 45 (44

and one for good luck, I guess). Cost is about $1 per key. The

bushings look pretty close to what was there before, except they're black

and they seem to have longer fins (unless the fins on my old ones were

worn down by age). The material they're made from is very pliable,

and they are sent covered in some kind of lubricant.

Installation was quite simple. Archive Sound has installation

instructions on their site (which you should read), but I thought it'd be

good to get some pictures while I had my Mini's keyboard out and write

first-hand what I did, since you may be thinking about doing this.

IMPORTANT: I AM AN

AMATEUR. I may be doing something wrong that'll wreck your machine.

It's YOUR machine, YOU take the risk if you follow my steps here. If

you know less than I do, you'd better take your machine to a service

person. I'm right on the edge of doing that myself. :-)

Tools required:

| Phillips screwdriver |

| Flat blade screwdriver |

| Some kind of tool to remove the old bushings. Long nose pliers

may work, but I had a long pin with a wooden handle from some kind of

old drafting set (no, I don't know what it was for, but I'm glad I had

it). I imagine a tiny but strong screwdriver may work as well.

Something of strong material with a small hook on the end may work the

best---slide it under the old bushing, hook on the back side, and

pry/pull! |

| Tie wrap |

| Someone to help steady the Mini while it's on its edge |

Steps:

Remove the Minimoog keyboard. I'd never done this before, but it

turns out to be really easy on

a Minimoog. Remember to call your friend over to help you when

needed.

- Turn the Mini over and remove the bottom cover.

- Mark the keyboard connector for easy reassembly--it is not keyed, so

mark it so you put the correct edges back together.

- Snip the tie wrap holding the connector together and unplug the

keyboard connector.

- Put the Mini up on its right hand edge.

- Loosen the screws holding the Pitch/Mod wheels. Remove them as

one unit and set on top of the Mini.

- Loosen the four screws that hold in the keyboard.

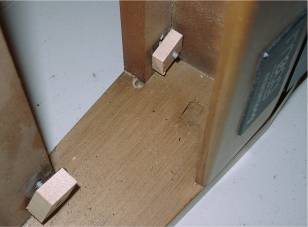

- There are wooden blocks on each of the four screws. Don't mix

them up, as they are different sizes for a reason. I labeled them.

- Gently tilt the front of the keyboard out from its usual resting

spot and pull forward, taking care that none of the wires are snagging

anywhere. Be careful not to hit the buss bar and spring contacts

as you remove the keyboard (replacing those contact springs or a bent

buss bar is major surgery).

- The keyboard should come right out.

Remove the old bushings. Some of these may be brittle or stuck

onto the keys, so be sure you get all the chunks out. The below

description is the "easy" way.

- Remove each key by unscrewing the slotted screw on the top.

Push the key forward, and it'll come off easily.

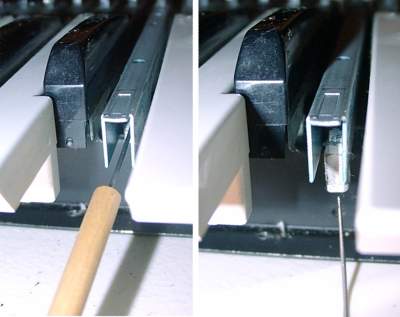

- Reach in under the metal part of the key with the tool to remove the

old bushing (very small screwdriver or---in my case---the big pin).

I jammed it underneath the bushing, pried up and pulled forward.

The old bushing should come out (in the picture on the right you can see

the old white/gray bushing getting dragged out), although it may be a

bit of a struggle. You may need to cut it up using some kind of

blade and remove the pieces. Remember to get all the chunkies out!

If you get stuck and cannot get the old bushing out, you can try the

"hard" way (it's not difficult, it just is slightly more involved).

- You don't need to remove the keycap, but if all you're removing is a

black key, you will need to remove any blocking white keys (or their

keycaps).

- Turn the keyboard around.

- Remove the spring on the back of the keyboard of the key you wish to

remove. I used long nosed pliers.

- Tilt the key up from the back until it clears its post, then push it

forward.

- The key slides off the front.

- You will clearly see the bushing. NOTE: You will also

see the "bellcap" that covers the rod that is pushed when you press the

key. Do not lose this. Put it back where it belongs before

you put the key back on.

For more information about the Pratt & Read keyboard, the kind of

contact cleaner to use, the kind of grease to use on the bellcaps, where

to get parts and more, see

Schober Organ

Notes No. 56.

Replace the bushings after you clear out all the old bushing's chunkies.

- There is no front/back for these bushings, so they can go on however

you want them to.

- My suggestion: Each bushing has two sides that are shaped like

a "V". This is top and bottom. Find the "V" that has a

little more material---it'll be a little thicker at the bottom of the

"V" than the other side. Let this "thicker" side be the top.

- Slide the hole over the holder and push as far as you can with your

fingers.

- Using a flat blade screw driver, push against that "thick" part of

the "V" until it won't go anymore, but be careful you don't wreck the

bushing. Then push on the bottom part to get it to go over the

bend in the holder. Push a little more on the "thick" side if you

have to. It should pop on without much fuss.

- If you have taken all the keys off using the "hard" way, you may be

able to push the bushing on using your fingers and no tools.

Screw your keycaps back on (or put your keys back on and reattach the

springs if you used the "hard" way), and you're ready to go.

That's all there is to it.

Now replace the keyboard, very much in the reverse order of removal.

Call your friend over to help again.

- With the Mini up on its side, slide the keyboard back in.

Don't lose any of the little wood pieces on the screws---make sure they

stay put. Get the keyboard as close to its original position as

possible.

- Slide the Pitch/Mod wheel section back in its place. Note that

the back edge fits into a slot in the wood (this holds the back part of

the Pitch/Mod wheel assembly in place---it just slides into the groove).

Tighten the two screws that hold it in place on the front.

- Now tighten the keyboard with its four screws on the very bottom of

the Mini.

- Reconnect the keyboard.

- Test the machine. If not working, fix.

- Replace the tie wrap on the keyboard connector.

- Put the bottom back on.

You're done.

So...Do the new keyboard bushings deliver as promised?

I knew you'd ask. Here's what I noticed straight away:

| The keys are all level |

| The action now has short, positive throws |

| The keys all feel the same---they are all now very consistent up and

down |

| No more annoying click from that key where the bushing was

disintegrated! |

| The keypresses don't feel "dead" as they did before---no "thunk",

there's a bit more zip to it |

After I got rid of the squirrely notes (see above), I put the Mini back

together and played it for a while. OSC 1 did me the favor of

working for a few minutes. Well, the verdict is in. If the

Mini wasn't addictive enough to twiddle and play already, it's now even

more addictive. The keyboard demands to be played. It's not

mushy like keyboards in other synths. It's crisp, it requires just

the right amount of pressure, and it feels solid. I know the Archive

Sound kit made a difference.

Can anything so simple as the Archive Sound replacement bushings make

such a huge difference in the playability of a keyboard? From that

I've seen, yep, renewing those bushings is a really good idea for the

tired ol' Minis out there and other keyboards using the Pratt & Read

mechanism. Look into it! |

Thank yous...

Man, I have too many people to thank for their patience and assistance.

In no particular order:

| Rich over at Arcsound |

| Don B. (DB Musical Electronics) |

| Harry K. (Minimoog YahooGroup) |

| "Synthfool" Kevin L. |

| Norm L. (Mellotronist) |

| Robert L. |

| "Padre" Alan R. |

| Don T. (Mellotronist) |

| ACK Supply, Mouser, and Radio Shack (of course) |

|